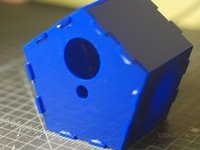

BirdHouse: A birdhouse made out of bio-plastic soon coming to the Casa? Yesterday, some of us attended a reading of our friend Michel Bauwens and got the opportunity to meet Erik, who opened our eyes of how easy it is to create our own customizable manufacturing capability.

BirdHouse: A birdhouse made out of bio-plastic soon coming to the Casa? Yesterday, some of us attended a reading of our friend Michel Bauwens and got the opportunity to meet Erik, who opened our eyes of how easy it is to create our own customizable manufacturing capability.

Erik is involved in the Fablab-movement and he spoke with us about his experience with RepRap's. These are 3D printers designed to be freely reproduced by anyone. The cost of making them yourself is 500 euro.

But here comes the funny thing: you don't actually have to buy these components to build up the printer, but you manufacture them through a different 3D-printer, by using shared digital designs, and then assemble them yourself.

So -just to repeat it to make sure you get it- you can use another 3D printer with free-source designs to build the components which you can then assemble into yet a new printer, that you can then use to produce yet another.

It is like making babies, but then without the sex :) Or for the scientists among us: it is a clone-machine. Or in yet other technical terms, the RepRap is largely a self-replicating machine that can be used for rapid-prototyping and manufacturing.

This article and this video about a commercial printer will give you a good idea what this revolutionary free-source product is about.

The raw material that the printer uses is plastic - but one can also recycle used plastic or create biodegradable plastics with ingredients such as potato starch - which is called polylactic acid bio-plastics. There is also an article on Instructables on how to build these bio-plastics.